Taxes applicable to New Jersey Customers only. Dismiss

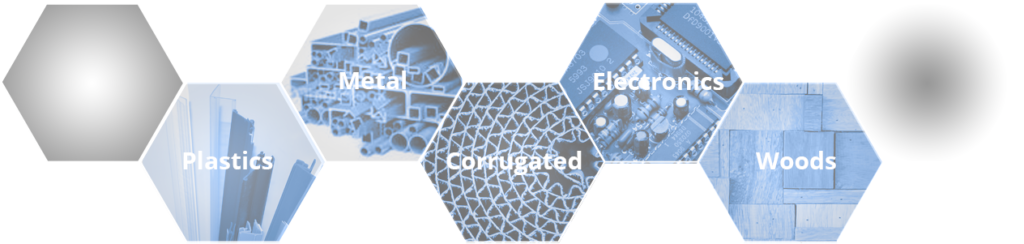

We assess your project scale, complexity and budget carefully before and during the design phase. We also consider the appropriate materials and best processes with our trusted suppliers. Manufacturing locations as well as domestic or overseas development are chosen to best fit your budgetary needs.

Numerous pre-qualified locations are used to insure sufficient capacity is available to handle the variety of manufacturing processes, order types, order sizes and delivery requirements.

We provide full assembly and FDA approved co-packing fulfillment services. Component production, display manufacture and customer product availability are coordinated to ensure co-packing delivery requirements achieved. Multiple plants in multiple geographic areas enable shipping to distribution centers or direct to retail. Diverse automated & semi-automated packaging lines as well as a flexible workforce used to handle seasonal cycles and surges.

We work directly with our customer’s distributions specialists to understand all logistics and requirements including:

Quality achievement and excellence is the cornerstone of our goal for client satisfaction. Display projects are tested for compliance during each stage of design, prototype build, production, shipping and installation.